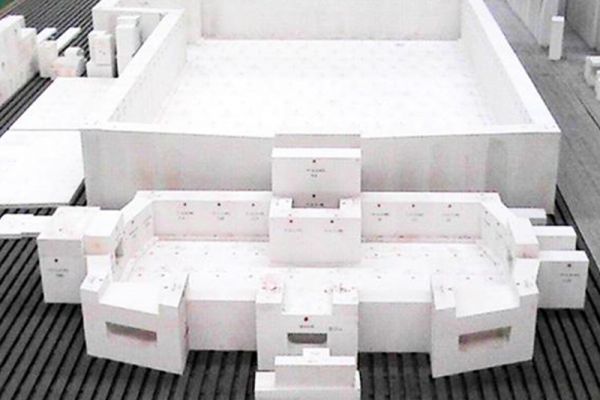

Haocorundum bricks are mainly used in large and medium-sized glass cellar melting pools, picture tube cellars, thermal storage room partition wall bricks, as well as in chemical plants and metallurgical industry cellar furnaces that are corroded by solutions.

What are the performance characteristics of zirconia corundum bricks

Zirconium corundum bricks are mainly used in large and medium-sized glass kilns, picture tube kilns, partition wall bricks for heat storage chambers, as well as in chemical plants and metallurgical industrial kilns that are corroded by solutions.

1. High quality insulation and temperature resistance

The use of more advanced insulation materials effectively reduces the thermal conductivity of this type of corundum brick. During use, the well evaluated corundum brick can effectively block heat transfer, while its strength is higher and its insulation stability is stronger, making its heat resistance and fire prevention effect more reliable under use. Nowadays, with the application of reliable and reliable corundum brick technology, the construction of transition and cooling belts in large rotary kilns has better quality, and this high-level corundum brick can be used to achieve more advanced fire insulation effects, making the corresponding cooling surface insulation more stable.

2. Characteristics of wear resistance and erosion resistance

Higher quality materials and more stable additives give it a solid and durable effect, while well reputed corundum bricks also have professional corrosion resistance, which can effectively resist erosion during use and achieve a stable and high-end application experience. The use of this unique corundum brick in rotary kilns can reduce the frequency of maintenance, extend the service cycle through its durable material, keep the temperature inside the barrel stable, and provide a better technical prerequisite for the safe application of thermal instruments.

From this, it can be seen that high-quality and reliable corundum bricks can meet the application needs of refractory materials today, providing better technical indicators for the application of chemical instruments. Utilizing this high-quality corundum brick can also improve the strength of its products, greatly enhancing their wear and corrosion resistance. Applying this well evaluated corundum brick can better achieve its stability and ensure the safe use of thermal instruments by closely integrating it with the equipment.